A borescope inspection is a full health check of the singularly most expensive component attached to your aircraft “The Engine”. This video inspection highlights the visible defects ensuring your asset is in a condition worthy of sale or purchase, lease or continued service.

Much of our work in this field is for Leasing Companies, Airlines and Maintenance Organisations performing pre-purchase, lease return and scheduled or non-scheduled maintenance inspections.

What is a borescope?

A borescope is the industrial version of the medical endoscope and is used in a similar way. That is to view or inspect something that is not easily accessible without taking apart or disassembly or major surgery in the case of the medical endoscope.

Another name for Borescope is Remote Visual Inspection or RVI for short. The “remote” refers to the fact that the operator’s eyes do not view the item directly, the item to be inspected is remote from the operator so the borescope is used to convey the visual image to the operator’s eyes. Borescopes are used in many different applications, we use them to look inside the casing of jet engines to see the internal parts.

Our Technology

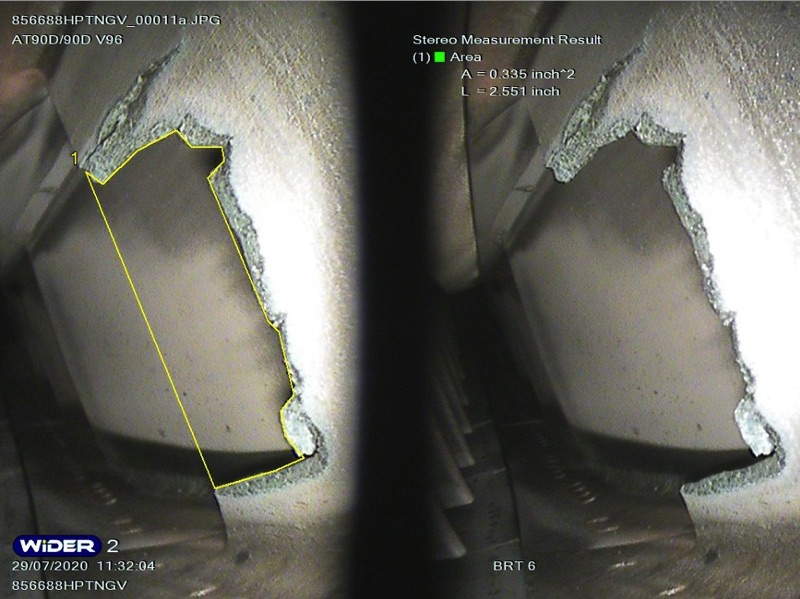

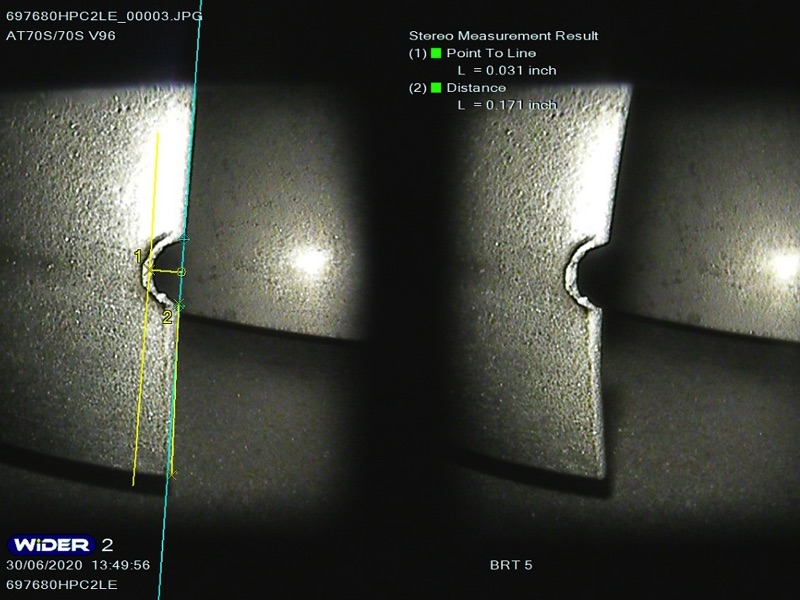

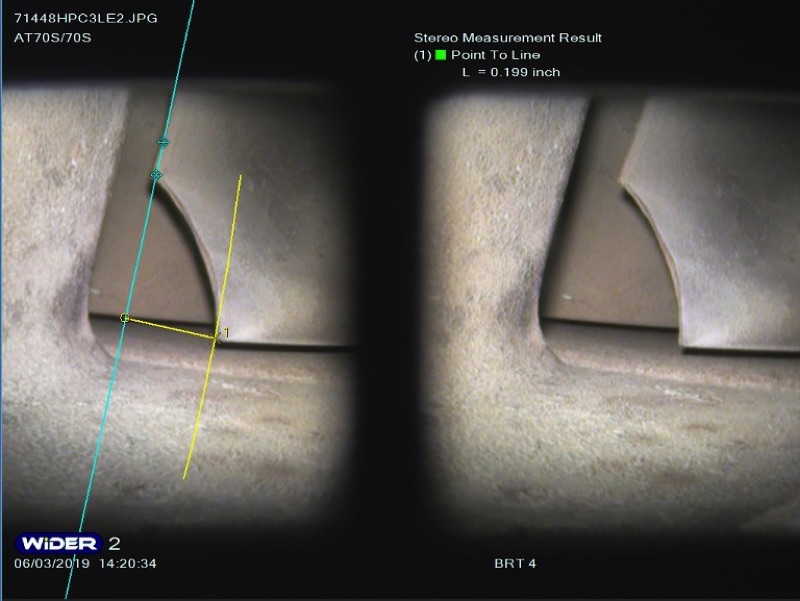

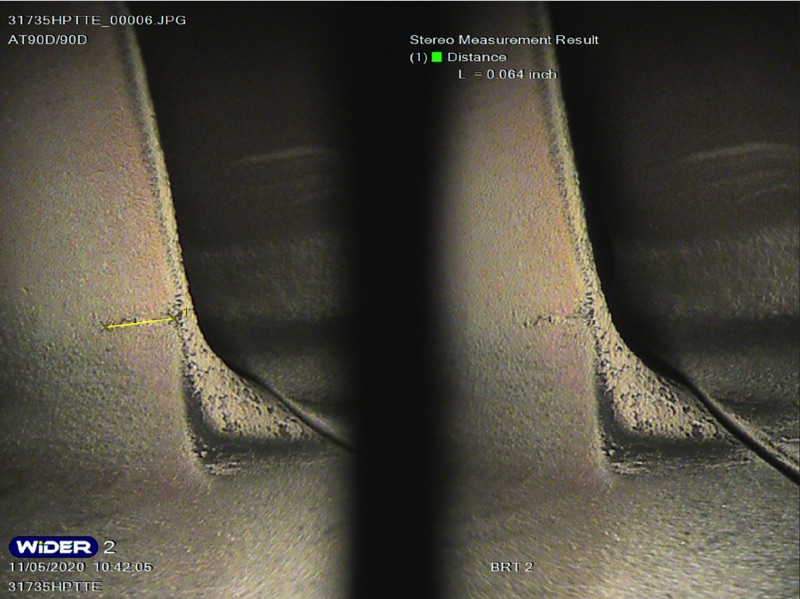

RVI Ltd uses the latest and most advanced flexible video borescope equipment produced by Olympus Industrial. We now own and use the latest Olympus Borescope System the IPLEX NX with advanced Digital Stereo measuring capability. The IPLEX NX kit has a 3.5m scope, 6mm in diameter with full 4 way electronic articulation. The light is produced by a laser within the kit body and the image is picked up by the video chip mounted in the tip under the lens adaptors. This kit is capable of very accurate measurement using a stereo system. The video clips are recorded in hi-definition video.

See below some of our measurement images. These have all been through the IPLEX “In help” software.