Emergency Inspection

Rapid-response inspections designed for immediate, non-intrusive assessment after unplanned events.

EMERGENCY INSPECTION

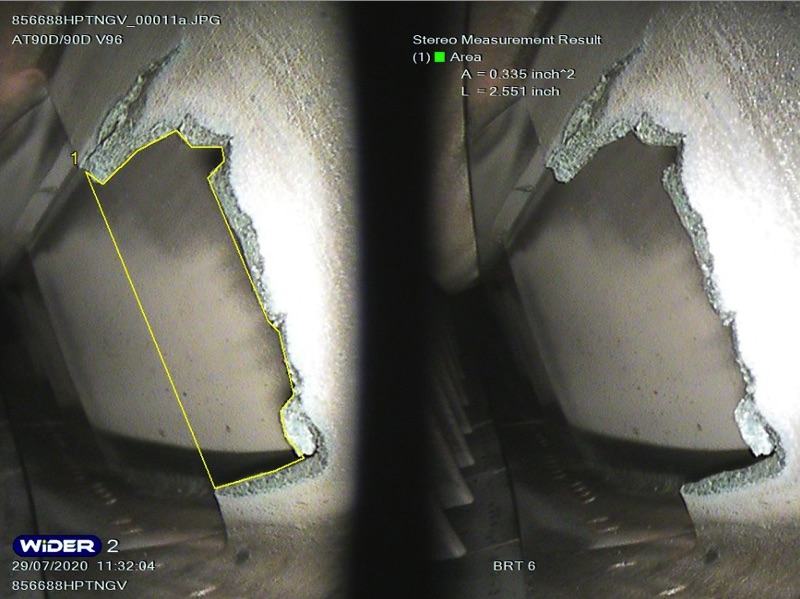

Emergency borescope inspections are deployed immediately following unplanned events that may compromise engine integrity.

These inspections allow for fast, non-intrusive internal assessments to determine serviceability, identify damage, and support critical return-to-service decisions.

Event-Driven Diagnostic Imaging

Initiated in response to engine surges, overtemps, bird strikes, heavy landings, FOD ingestion, or abnormal engine parameters. Inspections focus on suspected zones to identify cracks, blade deformation, burning, or uncontained damage.

Rapid Deployment, Minimal Downtime

Borescope kits and trained technicians can be mobilised airside or hangar-side within hours. Probes are inserted via standard access ports, avoiding engine teardown and enabling immediate visual confirmation of airworthiness or damage extent.

Real-Time Decision Support

Live imaging and video capture allow MROs and OEM support teams to review findings in real-time. This accelerates decisions on engine removal, repair, or clearance for continued operation, reducing AOG time and operational disruption.

EMERGENCY INSPECTION

Use Cases & Regulatory Alignment

Findings are documented according to manufacturer and regulatory defect classification systems. If damage exceeds AMM limits, follow-up actions are escalated per MEL dispatchability, minimising unnecessary removals while maintaining compliance with CAA/FAA/EASA safety protocols.